Experimenting with a Wooden Bevel Gear

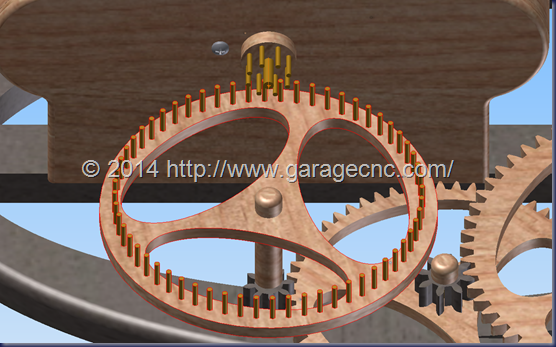

The original Clyton Boyer’s drawings was using a crown pinion and a wheel using rods as the teeth and this is what used for my initial design as shown in the picture from my 3D model below:

Later I thought that it would be an interesting challenge to make a wooden Bevel Gear instead of using the wheel with rods.

Making this with wood and by hand is very complicated but with the CNC is quite a simple task. After a couple of hours of design and CNC programing I was able to mill the pinion and the wheel really fast. Below a video of my CNC milling the wheel:

I made an initial design and test and this is how it looks like:

And it works! as seen in the following video:

There is still work to do as all the mounting is provisional, I need to build the proper wood spacers, the pinion of the wheel to drive the rest of the clock, the stopper. I need to cut the holes to reduce weigh on the wheel and I need to mill a new motor pinion as there is a mistake on the diameter of the hole so it fit loose in the motor shaft.

Anyway the important thing is that the concept works and this will be integrated in the clock.

Update:

I just finished the final version of the bevel gear and tested it with the pulse motor installed in the clock frame at full speed without the pendulum. The result is really nice and works quite and smooth

Here are some close-up views of the gears:

No comments:

Post a Comment

Please be aware that any comment with commercial links will be immediately deleted and declared as SPAM.

If you want to advertise in my blog please contact me to agree in a fee and i will be happy to add your link in the side bar.