Pythagoras is a very small clock and is a big challenge to built it as the wheel teeth and in general all parts are small. Wood is vey unpredictable material when working small cuts in the CNC machine.

First thing I want to build is the frame, the base and all the escapement mechanism.

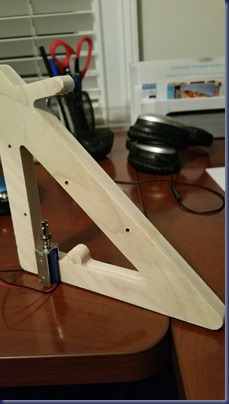

Today I worked on the frame. I used a 1/4” 1 flute bit. Speed about 10,000 RPM and a very slow feed rate about 5 feet per minute. As the CNC motors are stepper and not servos if by any chance the wood is so hard that the feed cannot advance you can have cumulative error. I prefer to go slow and avoid problem. One day I will make a servo driven router….

I made a mistake placing the drill bit in the CNC so what I did in order to not lose the work is I filled the wrong holes with a piece of rod and glue. Tomorrow I will open the holes manually.

The frame

Milling the frame:

Frame ready! Note the size compared with a pen. This will be a night table clock…

The slot to hold the solenoid was the correct size

Tomorrow I will work on the base and probably the escape wheel…

No comments:

Post a Comment

Please be aware that any comment with commercial links will be immediately deleted and declared as SPAM.

If you want to advertise in my blog please contact me to agree in a fee and i will be happy to add your link in the side bar.